-

2-Zone Thermal Shock Test Chamber

Thermal shock chambers are used to test composite materials and material structures to see how well they can withstand continuous exposure to high and extremely low temperatures. This means testing chemical changes or physical damage caused by thermal expansion and contraction in a short period of time. Applicable objects include metals, plastics, rubber, electronics and other materials.

Send Email Details -

3-Zone Thermal Shock Test Chamber

◆Adopt color touch screen control, friendly interface, and parameter recording function

Send Email Details

◆Lower defrosting times, greatly improving test efficiency

◆Conversion time is less than 10 seconds, and temperature recovery time is less than 5 minutes

◆R232, R485 output interface, realize multiple remote monitoring and control

◆Error information is displayed in real time, easy to troubleshoot

◆Expand the capacity of the test area

◆Can easily perform test product plus cable wiring operations -

Altitude Test Chamber with Temperature Cycling System

◆The equipment starts/stops using a panel switch button and the host computer controls two methods, both of which can be realized. Customers can operate according to the actual needs of the battery pack.

Send Email Details

◆The monitoring camera system monitors the appearance changes of the object in real time during the test, and records them in the video database for storage, which is convenient for analyzing the pressure damage events and damage methods of the battery shell material and their processes.

◆The impact protection cover box is composed of high temperature resistant, corrosion resistant (stainless steel), and flame retardant components. The reinforced design can effectively isolate the damage caused by fire and explosion during the test.

◆The setting of all control parameters, data acquisition, and video recording of the remote control monitoring system can be operated by a computer that is more than 30m away from the equipment.

◆The equipment is compatible with tests of domestic and foreign standards such as GB31241, IEC62133-2017, UL1642, and UN38.3. -

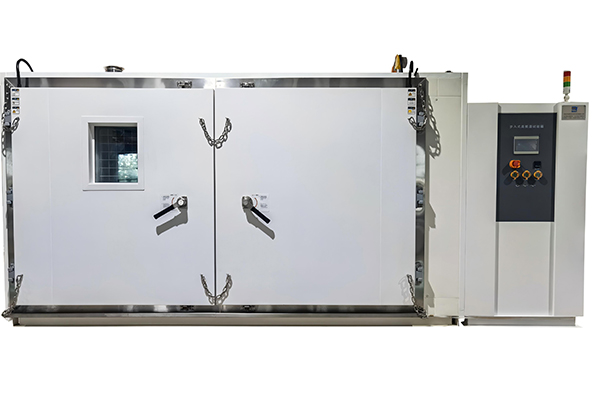

Walk-in Constant Temperature And Humidity Chamber

This test chamber is suitable for low temperature, high temperature, high and low temperature changes, constant humidity and heat, high and low temperature alternating humidity and heat tests of complete machines or large parts. The size and function of the studio can be changed according to user requirements. The block-type box has a beautiful shape and scientific air duct design to meet the needs of different customers.

Send Email Details -

Compound Salt Spray Chamber

Cyclic corrosion testing can provide the best laboratory simulation environment for natural corrosion. The latest research shows that the results of cyclic corrosion testing are very close to outdoor natural corrosion in terms of corrosion structure, surface morphology and relative corrosion rate. More complex cyclic corrosion tests require multi-step cycles, including salt spray stage, humidity, damp heat, drying, condensation, etc.

Send Email Details -

High Temperature Testing Chamber With Single Test Space

High temperature test is a method that uses a high temperature test chamber to determine the adaptability of products to storage, transportation, and use in high temperature climates. The severity of the test depends on the temperature and exposure duration. High temperature tests for polymer materials such as paint mainly include hot air aging, heat resistance tests, and heat resistance determination. Aging refers to the exposure of the sample rubber to a higher temperature than the use environment in order to obtain the effect of natural aging of the rubber in a short period of time. Heat resistance test refers to the test of the sample exposed to the same temperature as the use environment of the rubber.

Send Email Details