-

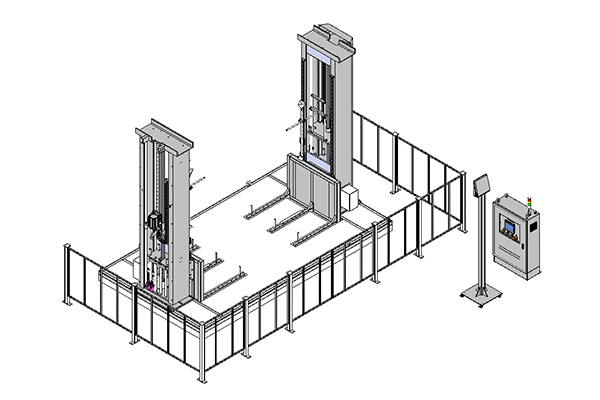

Battery Pack Drop Tester (Zero Drop)

It is mainly used for safety testing of battery packs and modules. The working principle of the battery drop tester is to lift the test sample to the set height through the lifting device, and then let it fall vertically and freely in a predetermined state to collide with the bottom plate plane (i.e., the impact surface), so as to complete the drop test process. Among them, the support arm is equivalent to the work surface, which is used to place the test sample and lift it vertically with the test sample. When doing the drop test, the support arm instantly disengages from the sample downward with an acceleration greater than 1g, so that the sample falls freely on the bottom plate. The drop height can start from zero, and it can be digitally set according to the test requirements, and the drop test is automatically performed according to the set height. The drop test bench adopts double-column guidance and electric buffering.

Send Email Details -

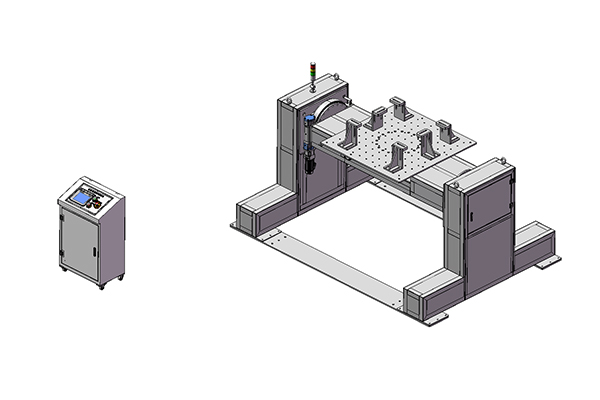

Rollover Testing Machine

The battery rollover tester is mainly used to simulate the battery pack or module installed in the electric vehicle, and observe the different conditions that may occur in the battery pack or system when the vehicle is driving uphill, downhill, rollover, or flipping at a high angle. Through experimental conditions, problems can be discovered, solved, product design optimized, and product quality improved.

Send Email Details -

Needle Puncture Extrusion Tester (Vertical)

The needle puncture extrusion tester is mainly used to simulate the safety and reliability testing of batteries after being punctured or extruded under different conditions.

Send Email Details

Pressure, displacement, voltage drop, and temperature can be used as control variables alone or in combination. The test will be stopped when any condition reaches the set value;

It has pressure, displacement, speed, type variable, temperature, and voltage data recording and real-time display of data curves;

It can set multi-step extrusion or multi-step needle puncture functions; The test chamber is composed of flame-retardant components such as high temperature resistance and corrosion resistance; The reinforced design can effectively isolate the damage caused by fire and explosion during the test;

Patent number: ZL201920401196.3 -

Short Circuit Test Machine

The battery short circuit tester is used to simulate the external short circuit of the battery. It uses a contactor as a switching element and a thermal relay as a protection device. When the circuit breaker is closed, the tested battery circuit is short-circuited. The equipment consists of a short-circuit device, a resistance device, a control system, a safety protection system, a temperature control system, a data acquisition system, etc.

Send Email Details -

Thermal Abuse Test Chamber

Thermal abuse test chamber is used to perform thermal abuse test on lithium battery according to GB/T36276 or GB/T36972, UL1973 and other test standards.

Send Email Details

The equipment is made of 5mm thick SUS304 stainless steel + external welded reinforcement ribs to ensure the strength of the inner box to prevent the impact of battery explosion from damaging the box.

Excellent algorithms are used to accurately control the temperature of the inner box, and the equipment performance fully meets the test requirements.

The excellent design reduces the energy consumption of the equipment, making it an energy-saving and environmentally friendly thermal abuse test chamber.

The equipment is designed with explosion-proof pressure relief port and a pressure relief door installed outside. When the pressure inside the box is too high, the pressure relief door will open.

The equipment door, pressure relief door and box body are connected with hinges and stainless steel explosion-proof chains to ensure the reliability of the equipment.