-

Heavy Object Impact Testing Machine

The battery heavy object impact tester is mainly used to simulate the safety and reliability test of the battery after being impacted. The battery is impacted by the free fall of the impact hammer to simulate the state of various CE battery cells after being impacted, and the test data is obtained at the same time, providing experimental data and basis for optimizing product design, as well as safety risk assessment and verification.

Send Email Details

Patent number: ZL202023200448.8 -

Drop Test Machine

This machine is suitable for free fall test of small consumer electronic products and parts such as mobile phones, walkie-talkies, electronic dictionaries, apartment intercoms, CD/MD/MP3, etc.; the machine adopts a pneumatic structure. The test piece is clamped in a special fixture (adjustable stroke), and the drop button is pressed to release the cylinder. The test piece will be tested by free fall. The drop height can be adjusted up and down. The altimeter can tell the drop height of the test piece. The key components of this machine have reliable performance and a variety of drop floors are available.

Send Email Details -

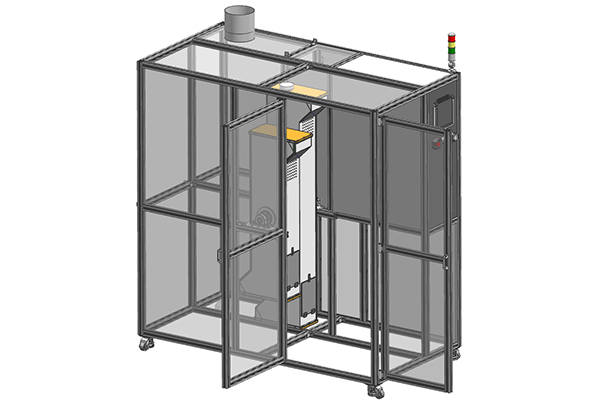

Micro Drop Test Machine

This machine is suitable for repeated drop tests on consumer batteries, mobile phones, tablet computers, etc. First, put the mobile phone into the drop fixture, adjust the appropriate size and position, and the motor drives the finger fixture to clamp the mobile phone. After rising to the set height, it is released, and the product falls freely. Repeat this until the set number of times.

Send Email Details

Patent number: ZL202120703962.9 -

Roller Drop Test Machine

This machine is suitable for tumbling and dropping tests of connectors, earphones, tablets, mobile phone batteries and other similar products. It has the function of touch screen setting and display. It is suitable for mobile phones, mobile phone batteries, PDAs, electronic dictionaries, CDs, MP3s and other small and lightweight portable electronic products as well as connectors, remote controls, adapters and other products to conduct continuous rotation (drop) tests. After the specified number of times is reached, the damage caused can be checked.

Send Email Details -

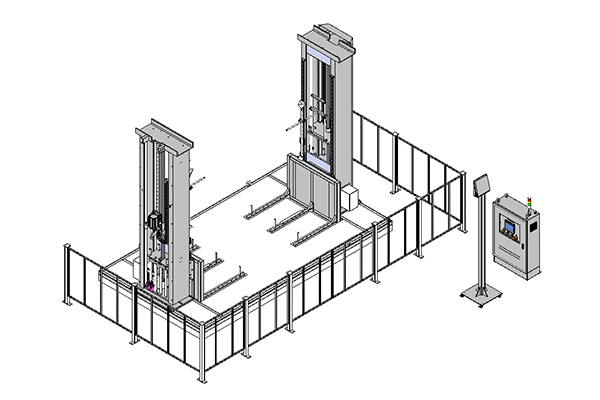

Battery Pack Drop Tester (Zero Drop)

It is mainly used for safety testing of battery packs and modules. The working principle of the battery drop tester is to lift the test sample to the set height through the lifting device, and then let it fall vertically and freely in a predetermined state to collide with the bottom plate plane (i.e., the impact surface), so as to complete the drop test process. Among them, the support arm is equivalent to the work surface, which is used to place the test sample and lift it vertically with the test sample. When doing the drop test, the support arm instantly disengages from the sample downward with an acceleration greater than 1g, so that the sample falls freely on the bottom plate. The drop height can start from zero, and it can be digitally set according to the test requirements, and the drop test is automatically performed according to the set height. The drop test bench adopts double-column guidance and electric buffering.

Send Email Details